Critical Metals Recovery & E-waste Analysis

We help recover valuable materials from electronic waste and characterize battery materials using precise analytical techniques. Our multi-technique approach provides the quantitative data needed for process optimization and quality control.

E-waste Characterization

Precious and platinum group metals analysis

in processed e-waste materials. XRF provides rapid elemental screening for gold, silver, platinum, palladium, and rhodium concentrations. SEM-EDX mapping identifies metal-rich particles and their distribution within ash or concentrate samples.

Complete elemental analysis

of circuit boards, components, and processing residues. We quantify valuable metals (Au, Ag, Pt, Pd, Rh) alongside base metals and potential contaminants to optimize recovery processes.

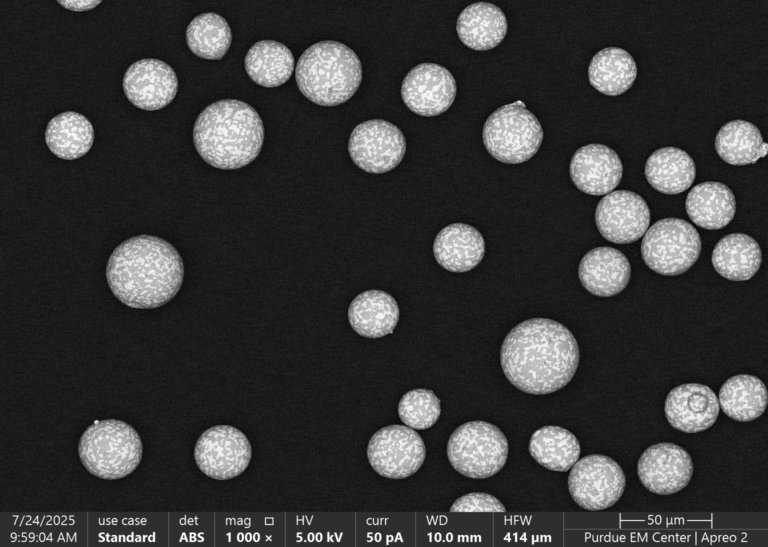

Particle analysis and liberation studies

using SEM-EDX to understand how metals are distributed and whether they're accessible for recovery. This helps optimize grinding and separation processes.

Battery Materials Testing

Lithium-ion battery material characterization

including cathode materials like LiFePO4. XRD analysis determines phase purity, crystallinity, and identifies impurity phases that affect performance.

Graphite analysis

for anode materials. We quantify the degree of graphitization using XRD and determine elemental composition. This is critical for battery performance and safety evaluation.

Battery recycling support

through elemental analysis of black mass and other processing intermediates. XRF provides rapid screening while XRD identifies mineral phases formed during processing.

Quality Control Applications

Our analytical approach combines rapid XRF screening with detailed XRD phase analysis and SEM-EDX microstructural characterization. This provides complete material characterization for process development, quality control, and regulatory compliance.

Sample requirements are typically 1-5 grams of powder or small solid pieces. Results available in 5-7 days with detailed reports including quantitative data and analytical methodology.

Optimize Your Critical Metals Recovery

Contact us to discuss how our analytical expertise can help maximize recovery efficiency and ensure quality control in your processes.

Get Started Request Quote