Industrial & Manufacturing Problem Solving

When something unexpected shows up in your manufacturing process, accurate identification is the first step toward a solution. We specialize in characterizing unknown materials, contamination, and product anomalies using combined analytical techniques.

Common Manufacturing Challenges We Address

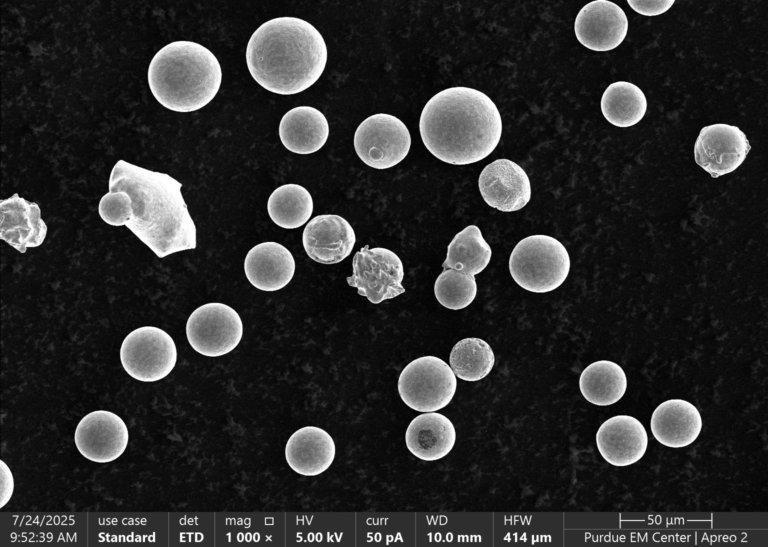

Unknown particles or contamination

in products, coatings, or raw materials. Using SEM-EDX for elemental composition and morphology, combined with XRD for crystalline phase identification, we can determine both what the contaminant is and likely sources.

Coating or surface treatment failures

where visual inspection isn't enough. Our approach combines surface analysis (SEM-EDX) with bulk characterization (XRF, XRD) to understand both surface chemistry and underlying substrate interactions.

Material property changes

in production. When mechanical properties, appearance, or performance shift unexpectedly, we identify compositional or structural differences using quantitative XRD analysis and elemental mapping.

Quality control for composite materials

including fiber-reinforced plastics, mineral-filled polymers, and metal matrix composites. We quantify filler content, distribution, and identify contamination that affects performance.

Internal structure analysis

using advanced 3D CT image processing. We analyze fracture networks and pore structure in rock samples, internal defects in manufactured products, and connectivity patterns in complex materials. This includes quantitative measurements of volumes, apertures, and 3D connectivity.

Analytical Approach

Rather than running standard tests, we work with you to understand the specific problem and select the right combination of techniques. Most manufacturing issues require multiple analytical methods - XRD for crystalline phases, XRF for elemental composition, and SEM-EDX for microstructural details and spatial distribution.

Our 20+ years of materials science experience helps identify the most informative analysis strategy and interpret results in the context of manufacturing processes.

Sample Requirements

We work with small samples - often just a few grams or even particles collected on tape. Most analyses are completed within 5-7 days. Contact us to discuss your specific situation and sample preparation needs.

Ready to Solve Your Manufacturing Problem?

Contact us to discuss your specific challenge and how our analytical expertise can help identify the root cause.

Get Started Request Quote